Safety First: Preventing Accidents in Scaffolding Operations | The Telangana Cement Factory Accident:

Safety should always be the top priority in any industrial setting, particularly in high-risk environments such as scaffolding operations. Recently, a tragic incident occurred at a cement factory in Telangana, resulting in the death of a migrant worker and leaving two others injured. This unfortunate event serves as a stark reminder of the critical importance of adhering to strict safety protocols in the construction and scaffolding industry.

The Telangana Cement Factory Accident:

The incident that took place at the cement factory in Telangana sent shockwaves through the construction and scaffolding community. Preliminary reports suggest that the accident occurred due to a scaffolding structure collapse, leading to a fatal fall for one migrant worker and causing injuries to two others. While investigations are still ongoing, early findings indicate that several safety lapses may have played a role in the unfortunate event.

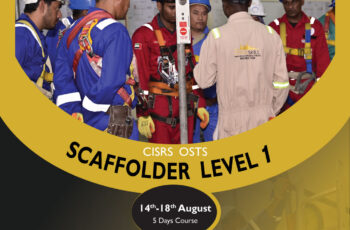

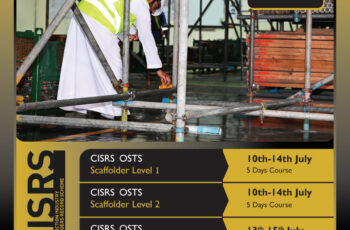

- Importance of Training and Education:

Proper training and education are paramount when it comes to scaffolding operations. Workers need to be well-versed in erecting, inspecting, and dismantling scaffolding structures to ensure their stability and safety. A comprehensive training program should cover topics such as proper equipment usage, load-bearing capacity, and risk assessment. Training not only equips workers with the necessary skills but also empowers them to identify potential hazards and report unsafe conditions promptly.

- Regular Safety Inspections:

Frequent and meticulous safety inspections are essential to identify any weaknesses or defects in scaffolding systems. These inspections should be carried out by competent personnel who can detect even minor issues that might lead to catastrophic failures if left unattended. Implementing a proactive inspection routine significantly reduces the likelihood of accidents and safeguards workers’ lives.

- Adherence to Safety Standards and Regulations:

Adhering to safety standards and regulations set forth by regulatory bodies is non-negotiable. Companies operating in the scaffolding industry must comply with local, state, and national safety guidelines. Failure to do so not only puts workers at risk but also invites legal consequences for the company. Emphasizing a culture of safety and compliance from the top-down can foster a safer working environment.

- Effective Communication:

Clear and effective communication among all personnel involved in scaffolding operations is vital. Workers need to understand their roles and responsibilities, and supervisors must ensure that safety protocols are consistently followed. Additionally, encouraging open communication channels allows workers to express safety concerns without fear of repercussions, promoting a safety-first approach.

- Personal Protective Equipment (PPE):

Proper use of personal protective equipment is a foundational aspect of ensuring worker safety. Hard hats, harnesses, safety gloves, and appropriate footwear are some of the essential PPE that must be worn at all times. Employers must provide these items and enforce their usage rigorously.